Products

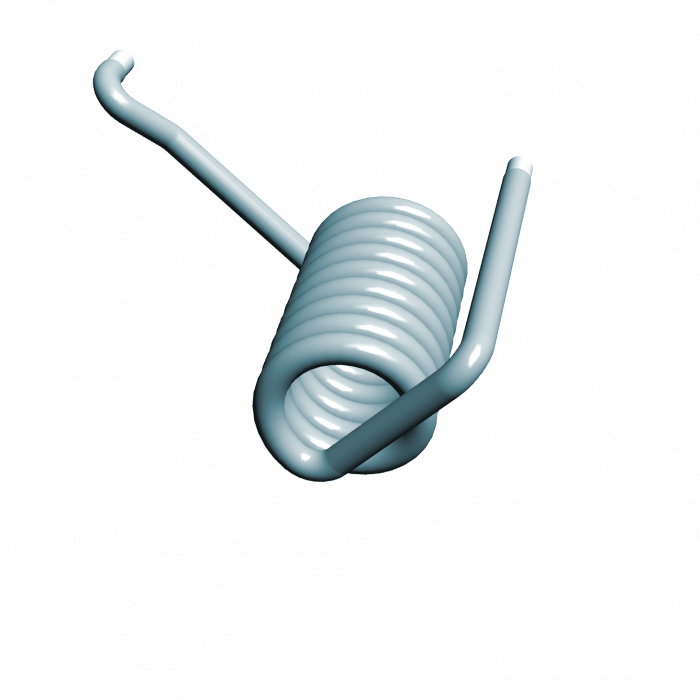

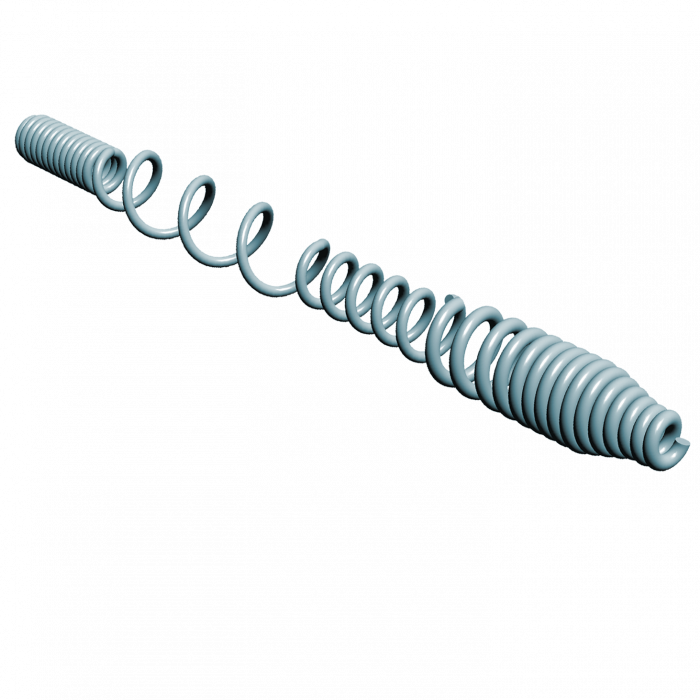

BAUMANN specializes in springs and stampings with demanding technical specifications.

Developing and engineering custom-made solutions to tight tolerances for large production series requiring stable processes is the heart of our business. Consistently focusing on the optimum production process enables us to guarantee optimum cost of ownership over the entire product lifecycle. In the interests of offering our customers the best possible products and solutions, we specialize in selected applications.

As a specialist provider, we are an innovative partner and technological spearhead in our field. We pick up new developments in design, material, production and coating processes as we spot them.

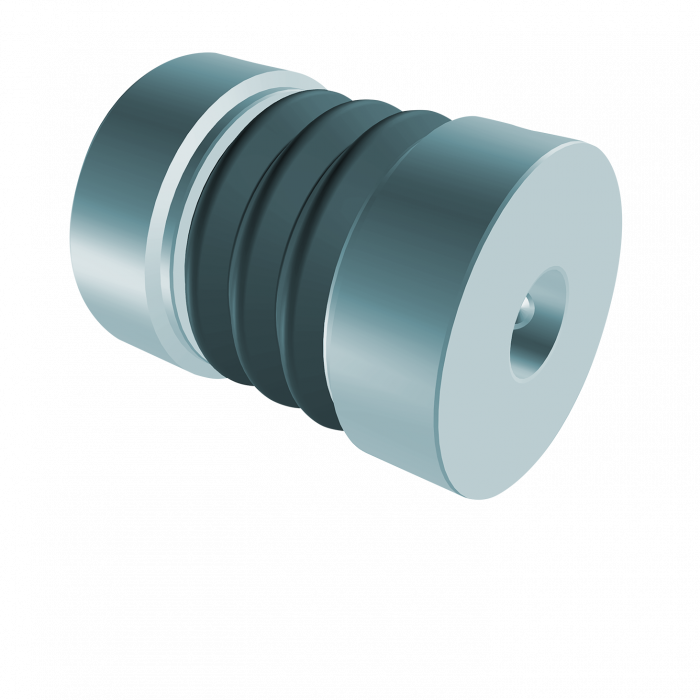

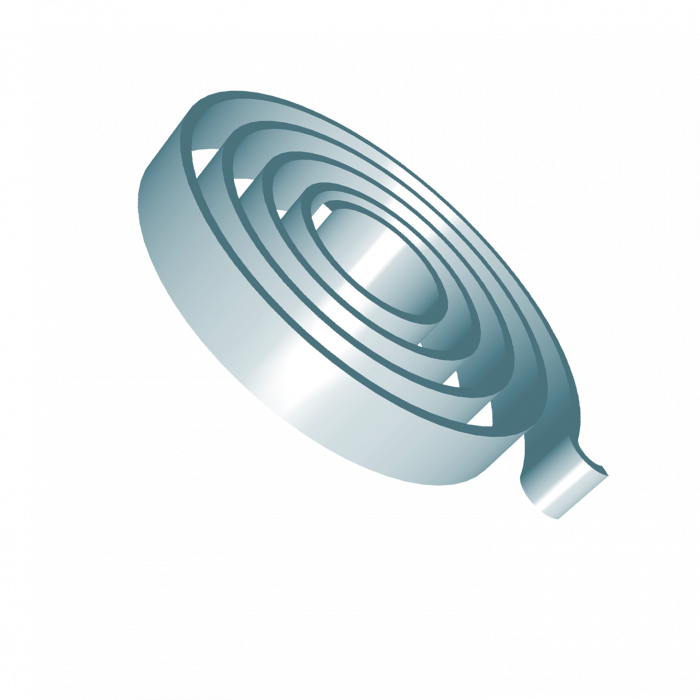

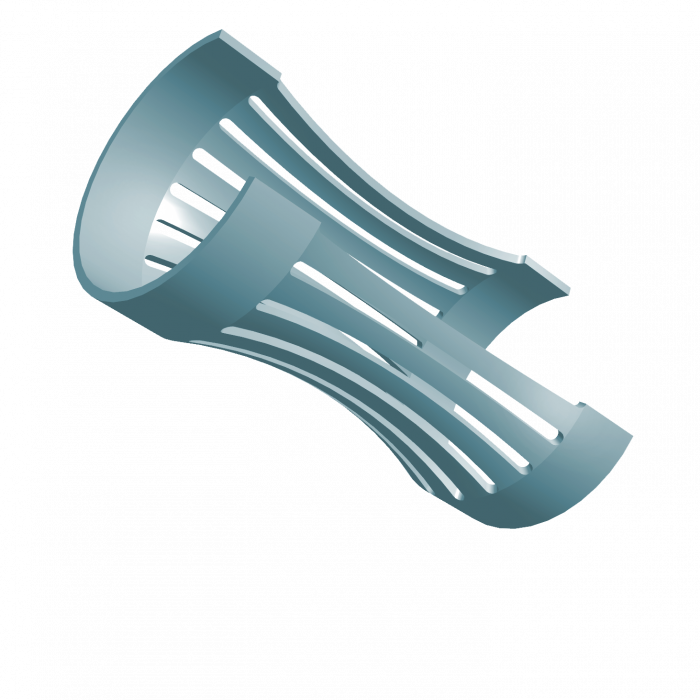

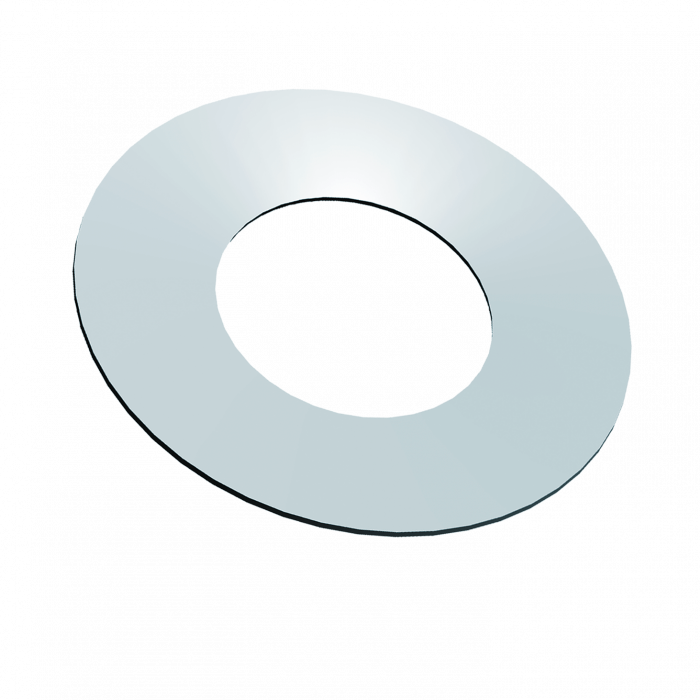

TYPES LM (light metal)

TYPES LM (light metal)

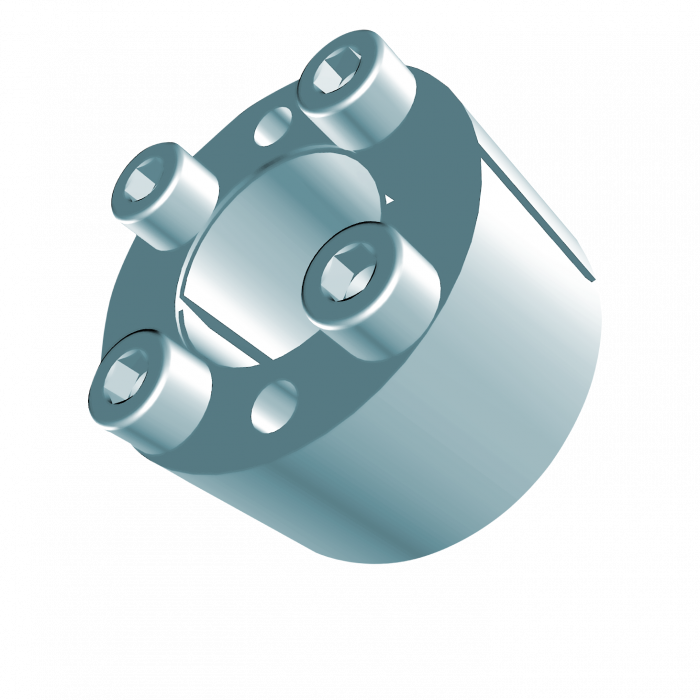

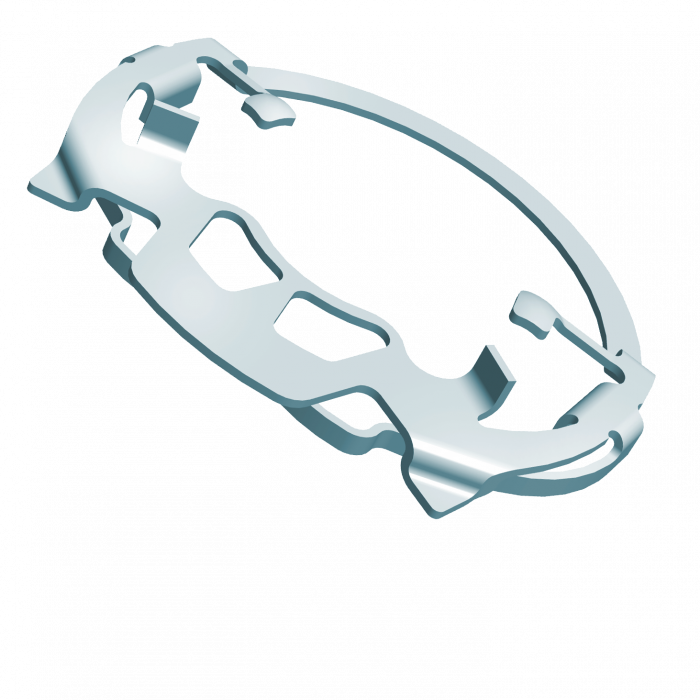

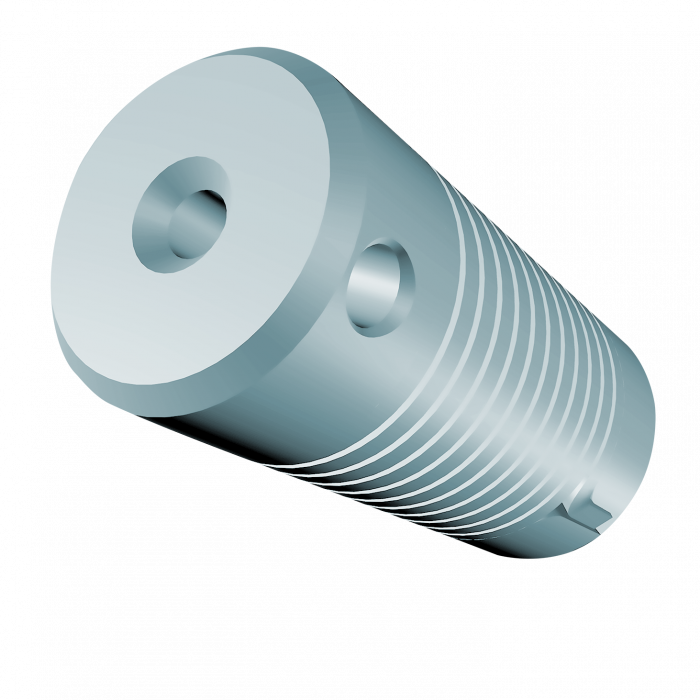

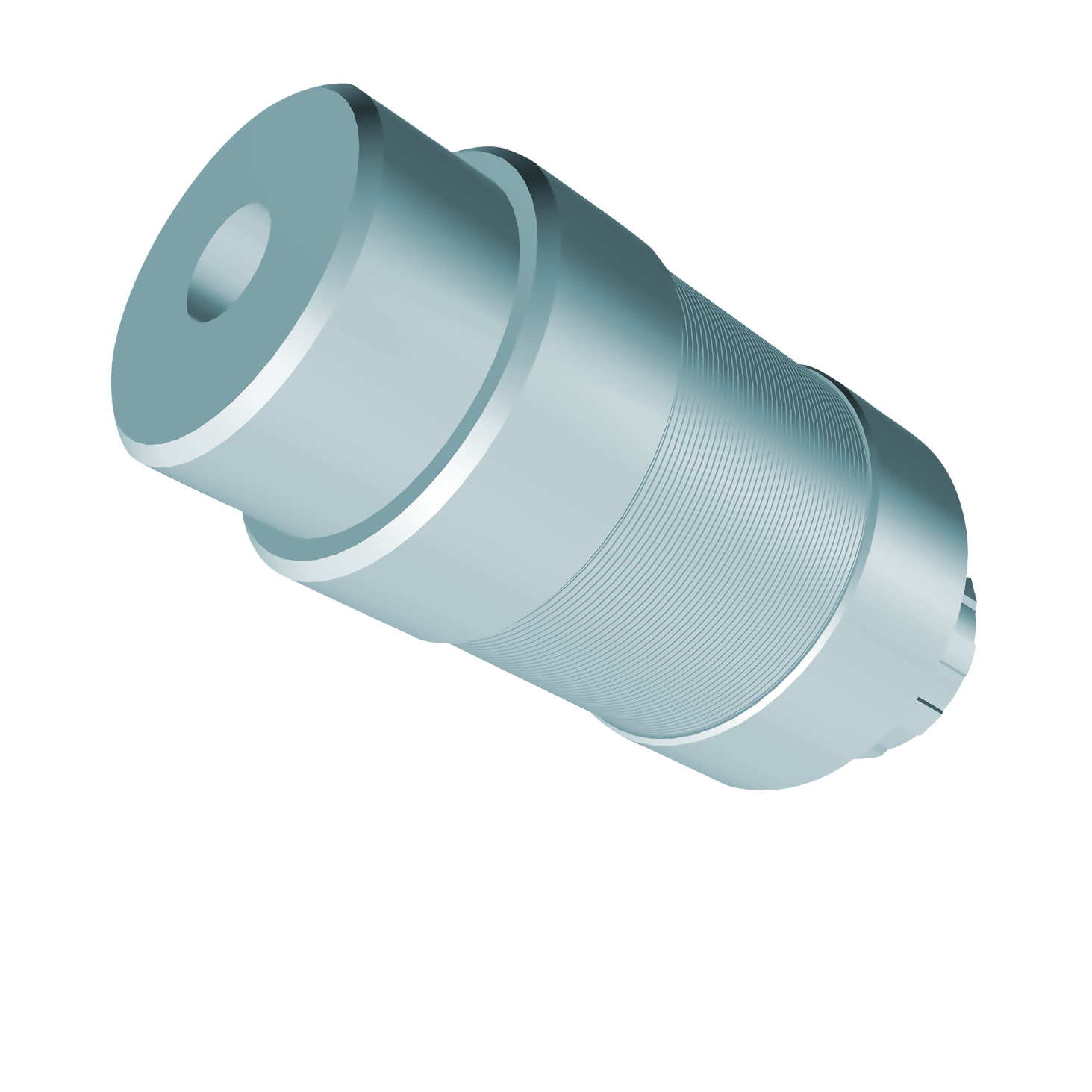

MM 24 K

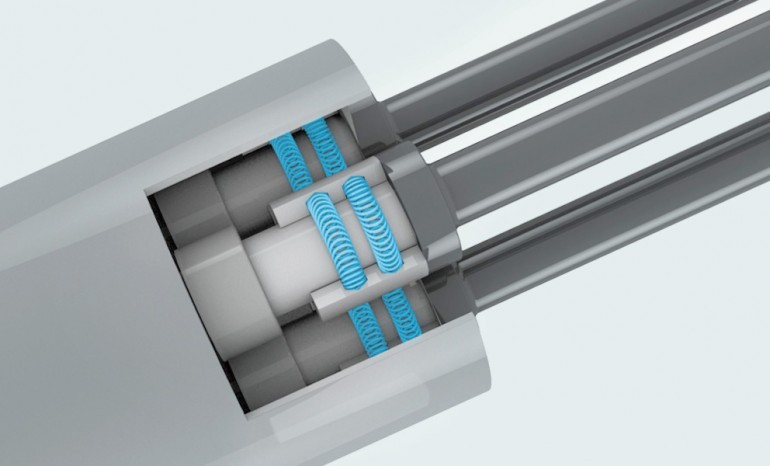

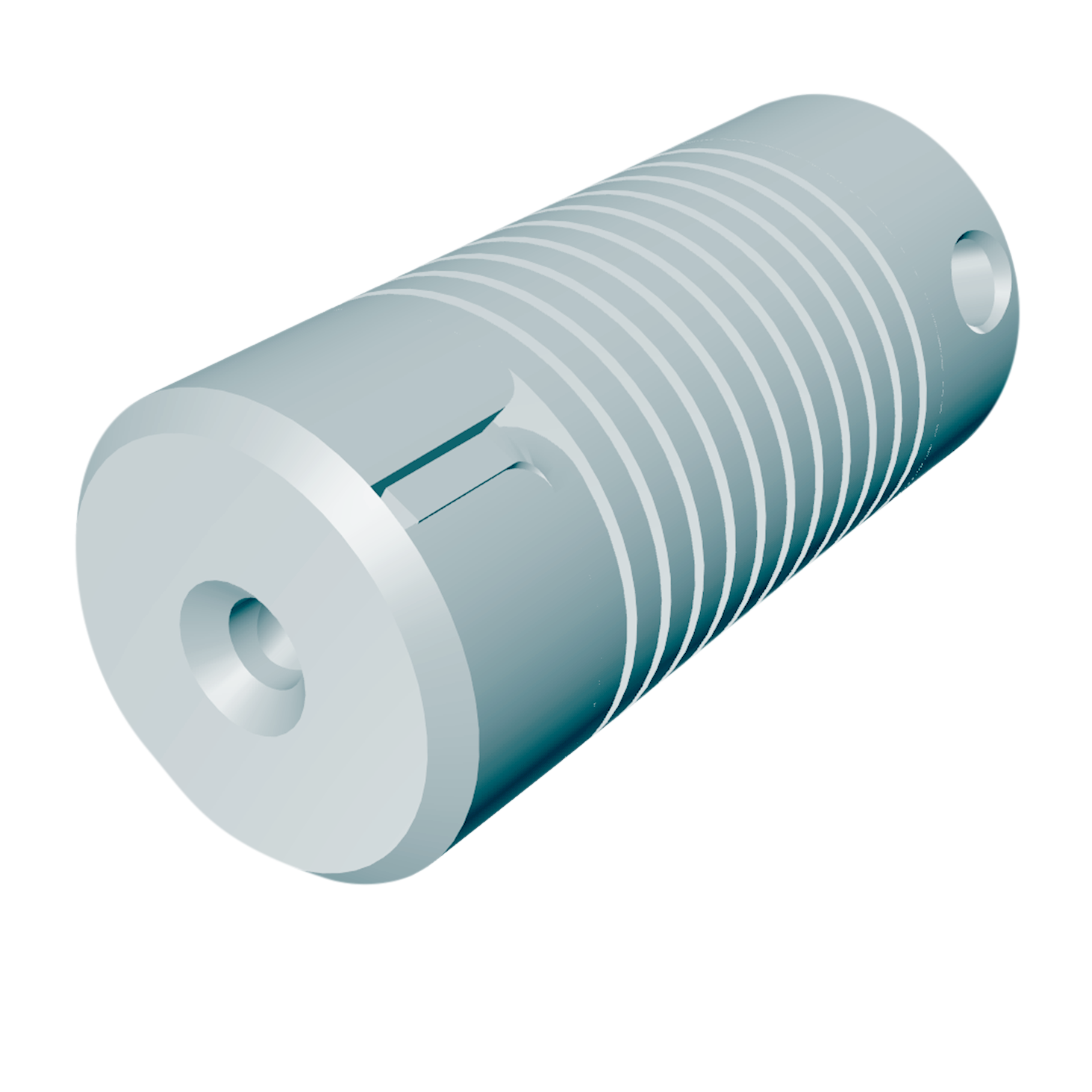

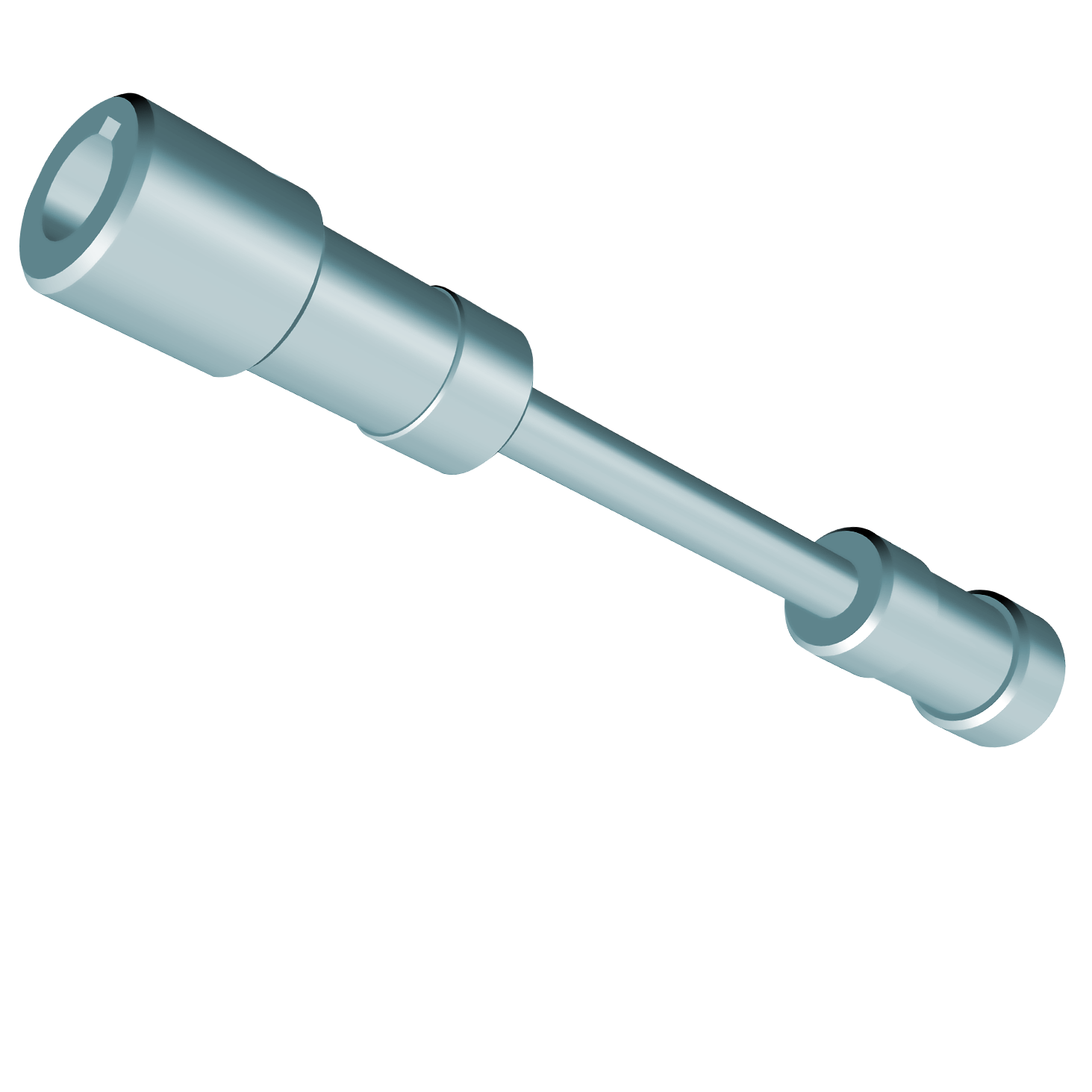

MM 24 K MM 12 K

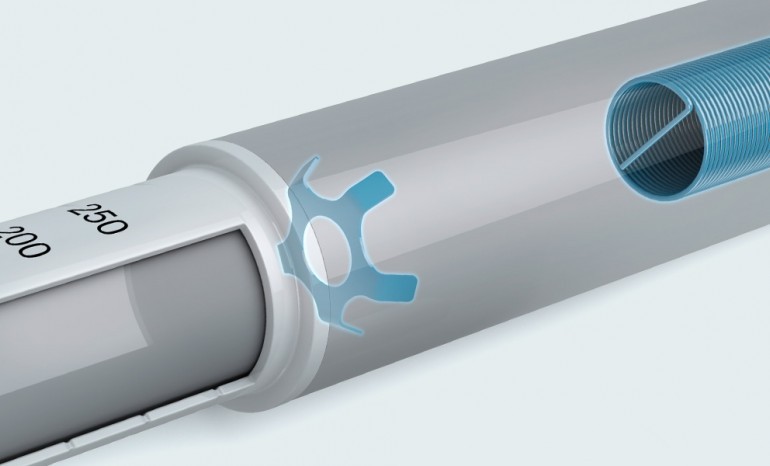

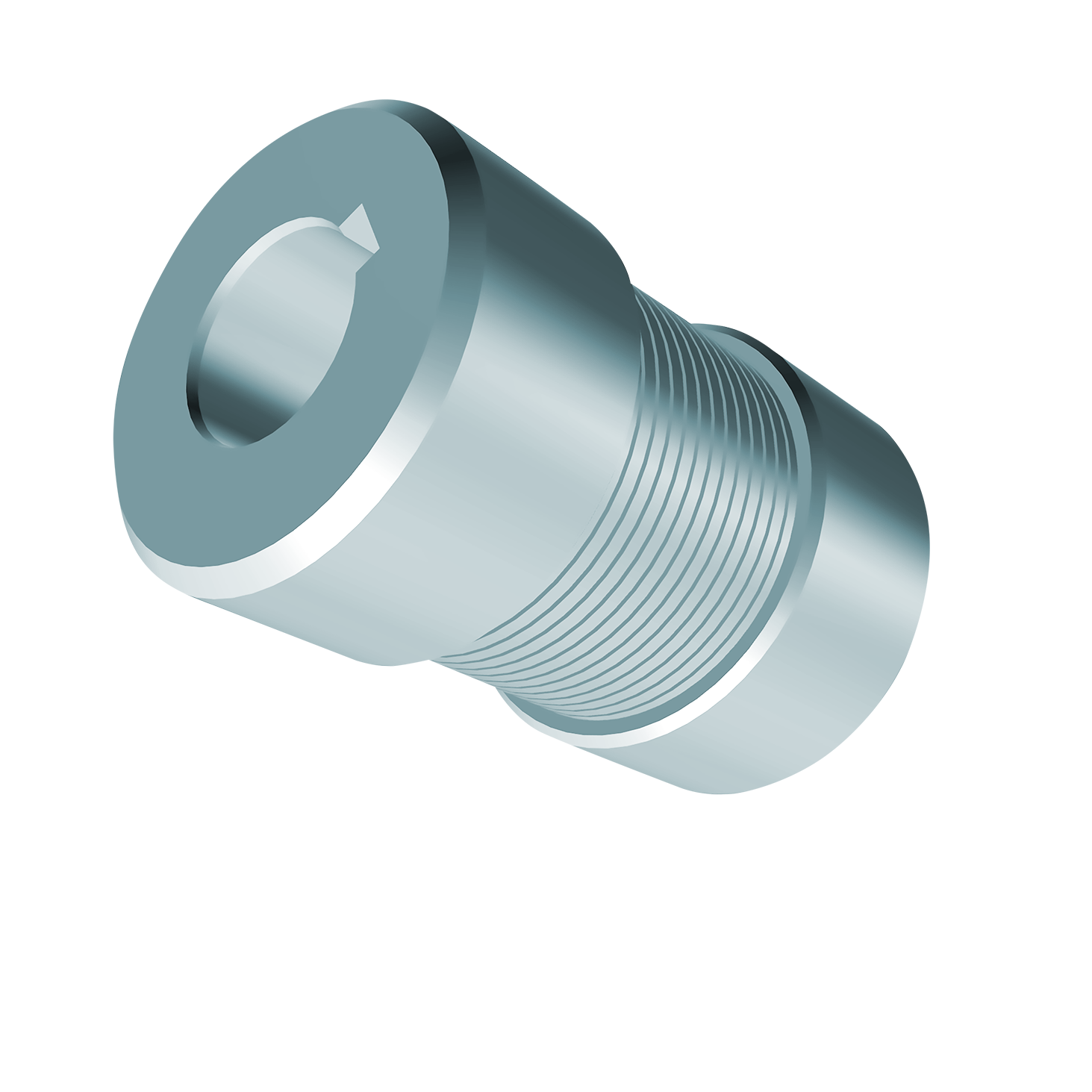

MM 12 K MM 12 L

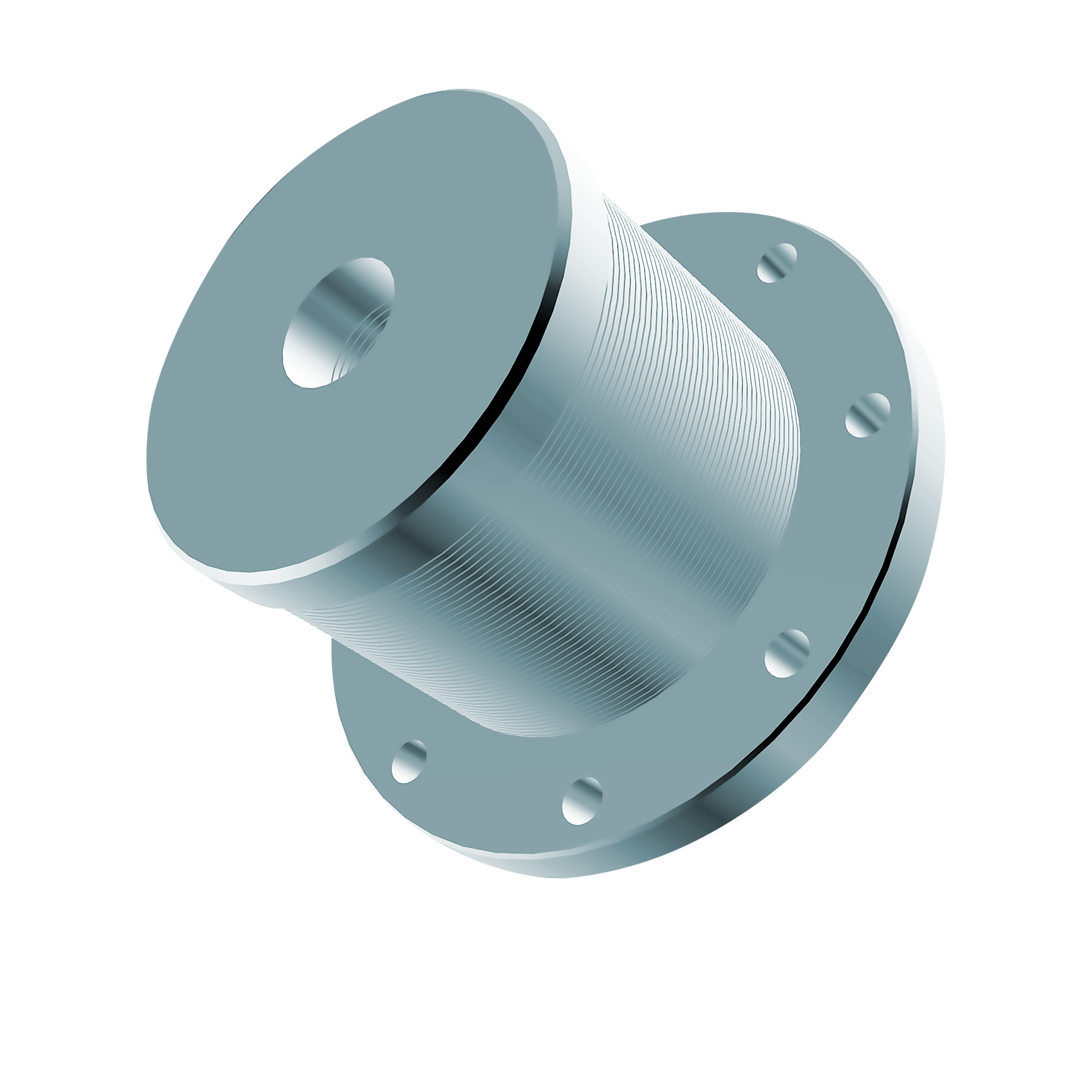

MM 12 L FN Special

FN Special